It delivers high tensile strength and superior abrasion resistance, featuring excellent processability with wide temperature processing window (160-220°C), while maintaining smooth and defect-free surface finish on final products.

Post-industrial PE Sheathing Compounds for Optical Cables

Product description

PE sub new sheathing material is made of new high molecular polyethylene as the main raw material, adding various additives, modified by blending, extruded and granulated by twin-screw extruder. The performance indexes can reach the standard of GB/T15065-2009 and YD/T 1485-2006. It has excellent processability of processing, mechanical and physical properties and electrical properties.

Processing technology

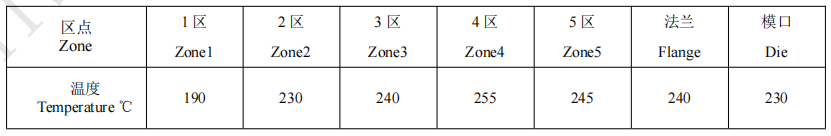

It is recommended that sub new PE sheath material should be processed with extruder having a minimum L/D ratio of 25. In the extrusion process, the production speed should be reduced and the plasticization should be ensured. It is best to dry before extrusion, and the maximum drying temperature is 100 °C. It is recommended to set the temperature (°C) of each zone of the extruder as follows:

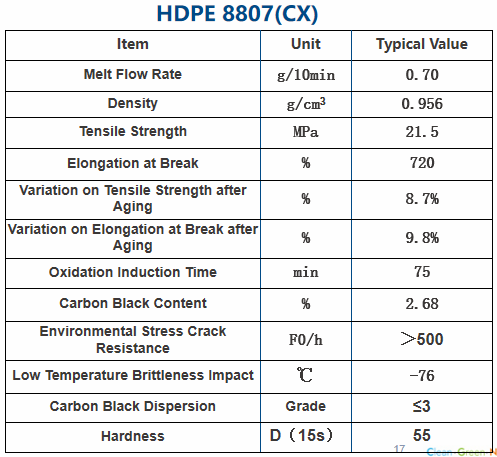

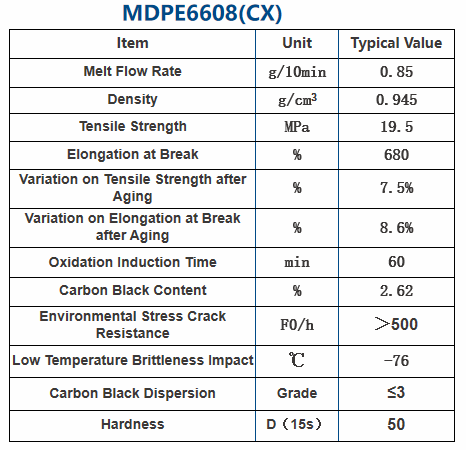

Properties

Storage and transport

Packaging: 500 kg, 750 kg, 900 kg polyethylene bag inside and outside woven bag for big package, or 25 kg paper-plastic composite for small package.

Transportation: The product should not be exposed to sunlight, rain or damp during transportation, and keep the packaging intact.

Storage: Please store in clean, cool, dry and ventilated warehouse; keep away from fire sources; if it was affected with damp, please dry under 80℃±5℃ for 1 to 2 hours.